OELs – A priority for Containment Solutions

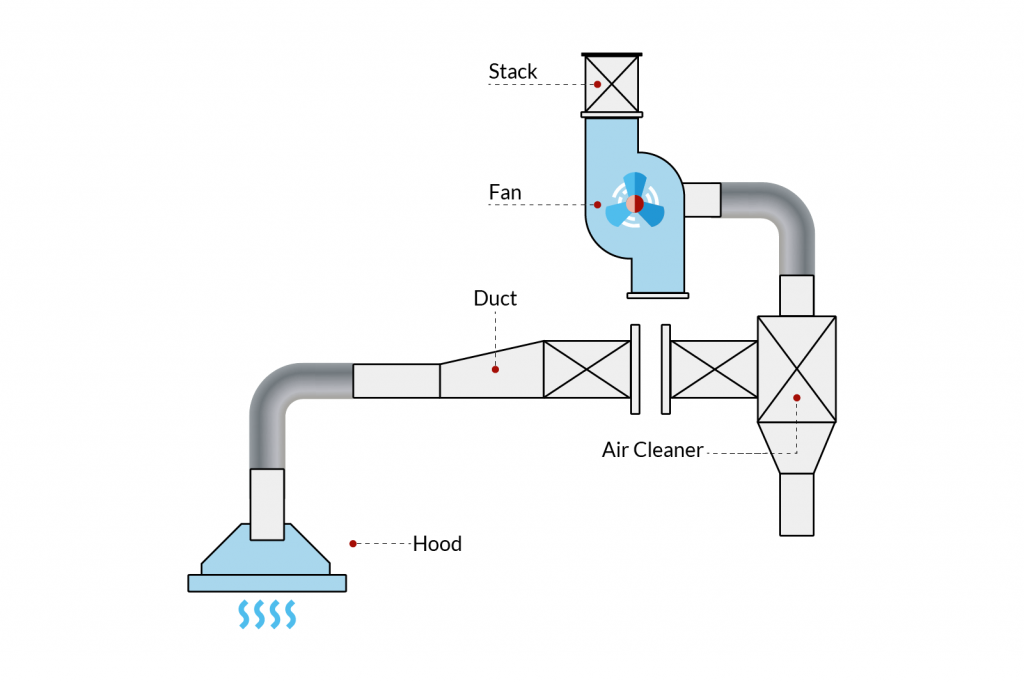

So why am I talking about Mr Tembe and kitchens in a blog post about Occupational Exposure Limits (OEL)? Kitchen chimneys are an excellent example of Local Exhaust Ventilation Systems (LEV) that help absorb the airborne contaminants including dust, fume, vapour, mist or gas in the workplace. They can be classified under OEL level 1 1000-5000 μg/m3.

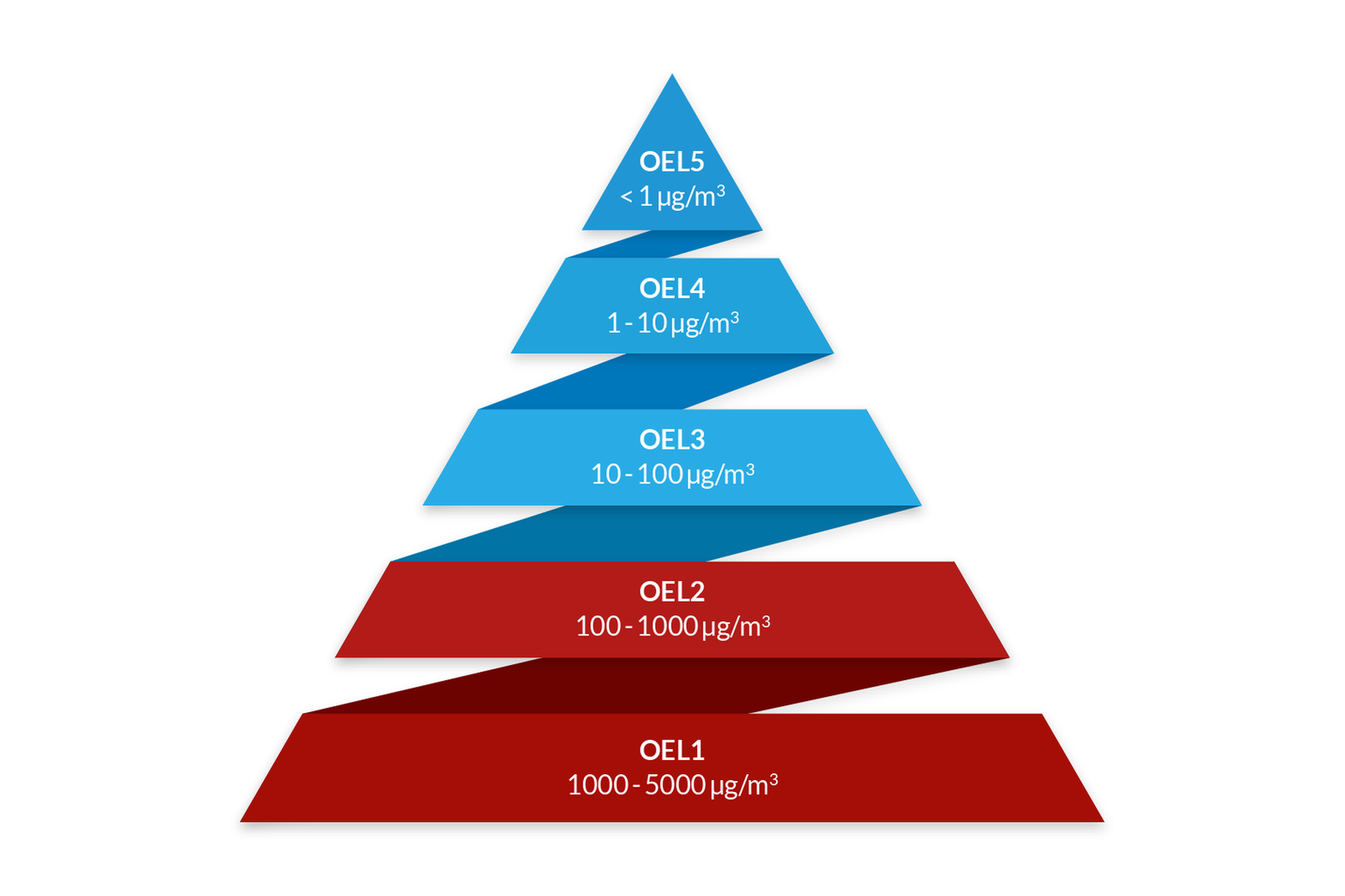

The OEL framework starts with a non-hazardous category and scales up to highly hazardous depending on the product category. Several toxicology studies highlight the adverse effects of chemical substances and explain how continued exposure leads to adverse health reactions.

Occupational Exposure Limit is the maximum exposure limit of hazardous substances in the air to which a worker can be repeatedly exposed over a longer duration (on an average 8 hours per day and 40 hours a week) without suffering any harmful consequences.

Perilous Particles

Until recently, the pharma industry had no guidelines around the manufacture of potent drugs. There was a lack of awareness around the dangers associated with exposure to hazardous substances and no process controls to protect employees from them. Moreover, an uncontained facility led to contamination of the processing area in the facility requiring more complex and stringent cleaning. A modern approach towards isolation systems has developed over the last 35 years. This approach includes efficiency in designs observed based on the 1950s – 70s that were far more prone to microbial contamination problems.

Particles in the air generated as a result of the manufacturing process put the equipment operator at risk, especially if the formulation contained a potent API in significant quantity. Cumbersome ‘moon suits‘ were the only protection available to operators from exposure to the drug manufacturing process or cross-contamination with other products manufactured within the facility. This lack of process control resulted in an increase in health complications to the employees working with such chemicals. Hazardous particles can cause damage to respiratory, dermatological or reproductive organs with prolonged exposure leading to long term complications.

Why OEL?

Occupational Exposure Limits (OELs) have been established to ensure standards of protection to workers’ health and safety. Lower levels of airborne particles (within the OEL limits) protect employees from occupational hazards or illness. Many companies establish specific OELs specific to the chemical or API in question; hence, it can vary from drug producer to producer. Moreover, due to the difficulty in obtaining pharmacological data, sometimes, it can be challenging to establish an OEL early in a product’s life cycle. Typically, OELs are created with the assumption they apply to healthy adults, over an 8-hour workday.

OELs use micrograms per cubic metre (m3) as a unit of measure. To illustrate: the average sugar crystal weighs around 3 milligrams. One microgram represents a particle that is 3,000 times tinier than one crystal of sugar! The diagram below depicts various OEL categories. The topmost part of the pyramid – OEL 5 represents dangerous or potent levels.

OEL Hazard Categories

Products or compounds are categorised according to hazard levels that correspond to these five OEL levels, as shown in the chart below.

Hazardous Substances without OEL

There are a large number of chemicals for which OEL levels are yet to be defined clearly. Manufacturing companies working with these substances must, at the very least, assign these chemicals to a particular category themselves. Alternatively, they can use the services of a company that offers exposure banding process. Doing so helps to identify control strategies critical for workers’ safety.

Containment Technologies and Solutions

Containment solutions are specially engineered to offer health protection and safety to staff working with both potent and aseptic substances as well as protect the work environment from these hazards.

Three critical factors must be considered while developing containment systems with process equipment integrations:

- Entry and Exit of Production Material

Protection from the potentially dangerous airborne particulate matter due to handling during the entry and exit. - Manipulation

Interact with and manipulate the material during the manufacturing of a batch. - Cleaning

Prompt cleaning of containment systems with minimal hands-on time and with no risk of exposure to dangerous compounds. Avoid cross-contamination for operator safety and to avoid the risk of exposure to dangerous compounds.

In addition to the above, validation and testing are key to Containment solutions.

The process of validating and defining the containment device according to the defined OEL level is known as surrogate monitoring. Surrogate monitoring is a complicated validation process to test whether the containment system is valid per the defined OEL category.

While many companies across the world manufacture containment devices, only a limited number of these actually pass rigorous surrogate testing.

In my next blog post, we will discuss how to perform the OEL validation process and the process of surrogate monitoring for containment systems.

Categories

Recent Posts

Subscribe

Never miss a post from Fabtech. Sign up to receive updates direct to your inbox.