A Day in the Life of a Project Manager – Part 2

This blog is a continuation of the Part I series A DAY IN THE LIFE OF A PROJECT MANAGER – PART 1. In the previous blog, I shared my customer and friend’s concern over an HVAC system validation they carried out for an MNC. It failed to achieve the required relative humidity for one of his company’s most important technology transfer projects. We wracked our brains on how to achieve a breakthrough in solving the problem.

ACHIEVING THE REQUISITE LEVEL OF HUMIDITY:

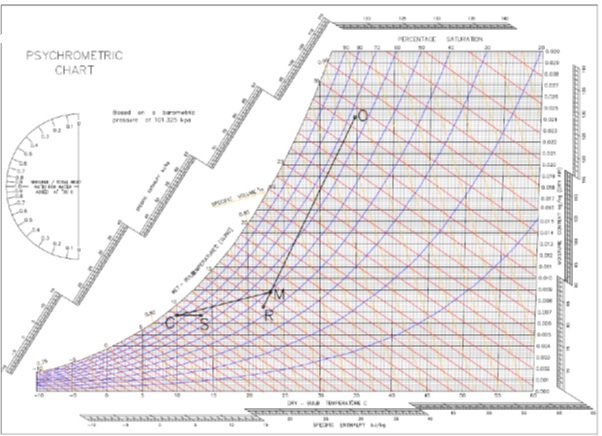

The next question was, how do we achieve the required levels of humidity? Generally and in practice, the air leaves the cooling coil near saturation level (with a relative humidity of 90% upward) due to the active dehumidification process. Therefore, to reach the 73% humidity level as mentioned (check data previous blog), the standard practice is to cool the air lower than the required temperature using the cooling coil, keeping the same humidity ratio level and later reheating the coil to increase the temperature and reduce the relative humidity as showing in the psychrometric chart in figure 3.

Illustration3: Psychrometric Chart of using cooling and reheating to control humidity

Illustration 3 represents the solution offered. Fresh Air (point O) is mixed with the Return Air from the room (Point R) in the mixing box ahead of the cooling coil (Point M). The parameters are mentioned below:

- Mixed air temperature: 22.9°C

- Mixed air relative humidity: 49.0%

- Mixed air Humidity Ratio: 8.58 g/kg

Later the mixed air passes through a cooling coil and leaves it (Point C) in line with the below-mentioned parameters before passing the reheat coil to reproduce the desired supply air parameters.

- Cooled air temperature: 11.4°C

- Cooled air relative humidity: 87.9%

- Cooled air Humidity Ratio: 7.45 g/kg

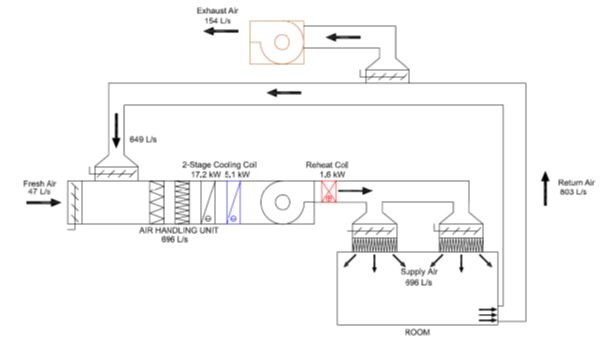

Thus we arrived at a solution requiring an additional cooling and reheating coil, as illustrated in Figure 4.

You may have noticed here that, as per my estimation that there was no requirement for a dehumidifier after all. A debate on using descent dehumidification during the process and especially in a pharmaceutical application has always existed. Thus, I prefer not to use it unless the traditional cooling and reheating solution don’t work. And there are varied opinions on usage; for example, when the latent load contributes more than 40% of the total load, any limit of humidity below 50% will force using descent dehumidification. I can’t entirely agree with that, and in my opinion, it is subjective to every case and cannot be used as a rule of thumb.

Figure 4: Suggested New HVAC System

ENGINEERING IS ECONOMY

The phrase “Engineering is Economy” has been aptly coined by my old friend and classmate/ co-worker at Eng Saff’a. Simply put, it is the economy that differentiates us from physicists who dream of multi-million-dollar laboratories to perform a rare astronomical experiment. We are bound by reality, honesty and duty towards our customers. For example, it may have been easier for me to ask Mr B to pay extra money to buy a completely new AHU, but where is the challenge here?

Coming back to the conversation with Mr B, the Engineering Head, I wanted to know if they owned an AHU currently not in use. And the positive reply was like a piece of music to the ears. They had a 5 RT DX-Cooling Coil used in an AHU serving an empty storage area. However, it was a struggle to dismantle and reinstall the new coil against the old one. And, as luck would have it, there was enough space to install it. See Illustration 5; hence we could include the DX-Coil in front as in Illustration 6 successfully.

Once we installed the cooling coil, it was easier to install the reheat coil, as duct heaters were already available in the local market. However, during the installation period, I was curious to know the nearest cooling coil factory to Lagos, Nigeria, its distance from the facility, the time required to manufacture a similar coil, and the time expected to deliver for installation?

WHAT IS LIFE ENGINEERING?

It just took 72 hours for us to be on track to resolve the issue that many Engineering companies may have charged exorbitantly. And this is what “Life Engineering” is all about. This process may seem like a simple installation for many experienced engineers.

Yet, the regular practice of procuring items may be unnecessary and have damaged our resources to an extent. While we appreciate innovation, we have become a consumer-driven society. A few of us may have forgotten why we become engineers in the first place and focus on commercial gains.

The knowledge that you’ve done something for someone else is a powerful reward and one that we hold on to as we bring our mission to life. This is the work we do at Fabtech, i.e. building pharmaceutical capability that gives doctors, researchers, lab techs and pharmacists their wings. It is why we call ourselves LIFE ENGINEERS.

Figure 5: Empty space in front of Chilled Water-Cooling Coil

Figure 6: Installing of new DX Cooling Coil

Monitoring and calibrating your system can seem like a long task, especially with a mechanical system where you cannot expect immediate results. There could be instances where you may have to wait for days together until you see the outcome and declare it a success. However, in a few cases, you may have to redo some of your initial work, for example, fear of wrong calculation. You can compare Illustration 7 to the previous night’s experience waiting for your good photos that are to arrive on your Whatsapp the next morning.

Figure 7: Resulting Temperature and Humidity Inside the room after modification

CONCLUSION:

I recollect that professors would caution us to consider various parameters instead of focusing on one single parameter during my Engineering days. This really helped me focus and kept me engaged throughout this journey that helped me crack the code.

As a part of Fabtech Technologies, it has been a rewarding journey. It has offered me the power to exercise my engineering knowledge to touch many lives across the globe. And now, the good news – the MNC has awarded Mr B’s facility’s approval for manufacturing a new product in Nigeria. Enabling countries like Nigeria and many other African countries to manufacture their medicines means affordable and accessible life-saving drug. This is the ethos of life engineering.

Categories

Recent Posts

Subscribe

Never miss a post from Fabtech. Sign up to receive updates direct to your inbox.